GSK988T TURNING CENTER CNC SYSTEM GSK988T is a new CNC controller for slant bed CNC lathe and turning center, adopt micro processor of 400MHz high performance, and it can control five feeding axes (including C axis), two analog spindles, real-time communication between GSKLink serial bus and servo unit, the adapted servo motor adapts encoder of absolute type in high resolution, realize position of 0.1um, and satisfy the requirements of combined processing of turning and milling in high precision. GSK988T is equipped with internet interface, and it supports remote monitor and file transmission and satisfies the requirements of internet education and workshop management. GSK988T is the best choice for slant bed CNC lathe and turning center. Characteristics: l Five feeding axes(including C axis), any three axes linkage, two analog spindles, support combined processing of turning and milling. l Command unit: 1um or 0.1 um is selected, maximum speed is 60m/min, when it is 0.1 um, and the maximum speed is 24m/min. l Adapted with servo unit of GSKLink, and realize servo parameter reading and writing and servo unit real-time monitor. l Through serial bus, it can extend I/O unit and GSKLink axis. l Built-in many PLC programs, PLC ladder diagram is edited on-line, real-time monitor. l Background edit part program. l Equipped with internet interface, support remote monitor and file transmission. l With USB interface, it supports file operation, system configuration and software upgrade in flash disk. l With 8.4’’ true color LCD, it support two-dimensional traverse path, display in stereogram Technical Specification Control axes l Maximum axes: five axes (including C axis) l Maximum linkage axes: three axes l Number of PLC control axes: five axes l Number of GSKLink axes: two axes Feeding axis function l Minimum command unit: 0.001mm or 0.0001mm is selected. l Position command range: ±99999999 x minimum command unit. l Rapid traverse unit: When the command unit is 0.001mm, the maximum speed is 60m/min. When the precision is 0.0001mm, the maximum speed is 24m/min. l Rapid override: Total four levels: F0, 25%, 50% and 100%, real-time adjusting. l Feeding override: Total 16 levels: 0~150%, real-time adjusting l Interpolation mode: Linear, arc, spiral and polar coordinate interpolation and rigid tapping.

Thread function l Common thread (following the spindle)/ rigid thread. l Single-headed/multiple thread of straight, taper and terminal surface in metric system/inch system , equal and variable pitch thread. l Thread retraction length, angle and speed characteristics can be set. l Thread pitch: 0.01mm~500mm or 0.01inch~9.99inch. Acceleration and deceleration function l Cutting feeding: Linear type or index type is selectable. l Rapid traverse: Linear type. l Thread cutting: Linear type or index type is selectable. l The starting speed, finishing speed and time of acceleration and deceleration are set by the parameter. Spindle function l Analog voltage 0V~10V output in two channels, spindle encoder feedback in two channels and two-spindle control. l Spindle speed: it is set by S code or PLC signal, the speed range is 0rpm~20,000rpm. l Spindle override: Total 8 levels: 50%~120%, real-time adjusting. l Spindle constant surface speed control. l Rigid tapping. Tool function l Tool length compensation. l Tool wearing compensation. l Tool nose radius compensation (C type) l Tool life management. l Methods of setting tools: Tool-setting in fixed position, trial cutting tool-setting, return to reference point for setting tool l Tool offset mode: Rewriting coordinate mode, tool traverse mode Precision compensation l Backlash compensation l Pitch error compensation in memory type PLC function l 13 types of basic commands, 30 types of function commands l PLC ladder diagram edit on-line, real-time monitor l PLC program in two levels, maximum 5,000 steps, the refresh cycle of the 1st level program:8ms l Support PLC warning and PLC alarm l Support many PLC programs (maximum 16), the current running PLC program can be selected by parameter I/O unit l Basic I/O: Input in 40 points/output in 32 points l Operation panel I/O: input in 96 points/output in 96 points l I/O extension: Use GSKLink for extension, the maximum is to extend two I/O ports, each input in 16 points/output in 8 points Man-machine interface l Display in Chinese and English, etc. l Display in two-dimensional tool path and stereogram l Servo state monitor l Servo parameter configuration on-line l Real-time clock l Help on-line Operation management l Operation mode: Auto, manual, edit, MDI, DNC, MPG and reference point return l Operation authority of multiple levels management l Alarm record l Ime turn off Editing program l Program memory capacity: 25M, 10,000 programs (including subprograms, macro programs) l Editing function: Edit in full screen, support the background edit of part program l Editing function: Program/block/character research, rewriting, deleting, block copy/block deleting l Program format: ISO codes, it supports the commands without space and hybrid programming of relative coordinate and absolute coordinate l Macro command: Support macro command programming in sentence type l Calling program: Support the macro program calling with parameter and subprogram nesting of 12 layers l Grammar check: Check grammer after editing the programs. Communication function l RS232: Transmit the files of part program and parameter, etc, DNC processing, support PLC program and software serial port upgrade. l USB: File operation, directly process files and support PLC programs in flash disk and software flash disk upgrade. l LAN: Remote monitor, internet DNC processing, file transmission, support PLC program and remote software upgrade. Safety function l Emergency stop l Hardware travel limit l Travel limit in many memory types l Data restoring and recovering List of G Codes

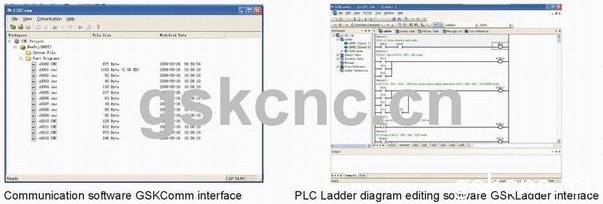

Communication Software PLC and Ladder Diagram Editing Software

The communication software GSKComm and PLC ladder diagram editing software GSKLadder of GSK988T

are all run in WINDDOWS98 /2000/XP. User can edit part program on PC, upload and download files

of part program, parameter, tool compensation and thread compensation, etc between PC and CNC,

as well as DNC real-time processing. The machine manufacturer can edit the ladder diagram on

GSKLadder of PC, upload and download PLC program between PC and CNC also.

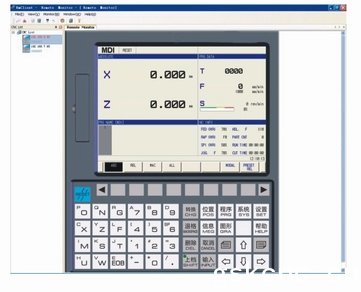

Remote Monitor Software: GSKMonitor

GSKMonitor runs under WIN98/2000/XP, and remote helps and monitors GSK988T through LAN interface.

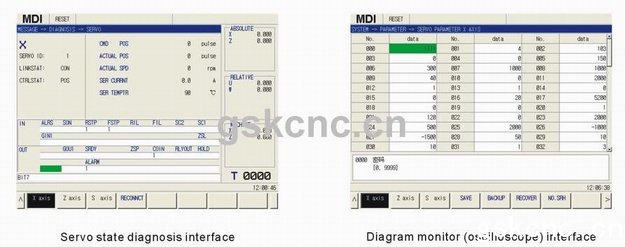

Servo State Diagnosis And Monitor

Through GSKLink, GSK988T realizes diagnosis and monitor of servo state(command position,

feeding position, motor speed and motor current, etc.)

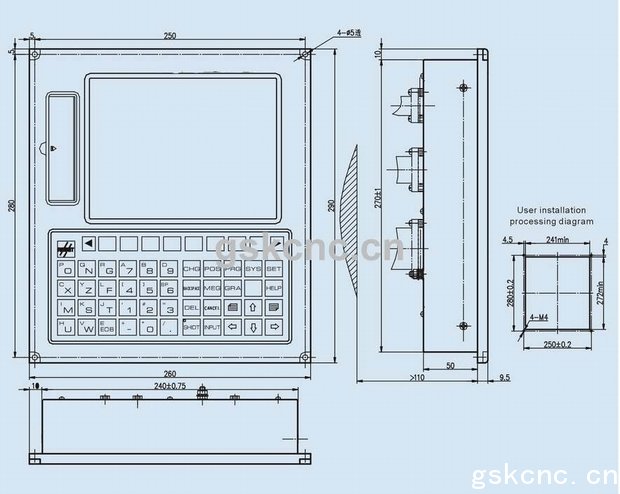

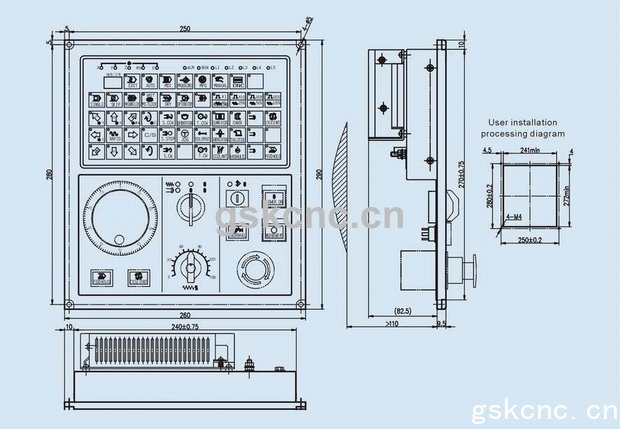

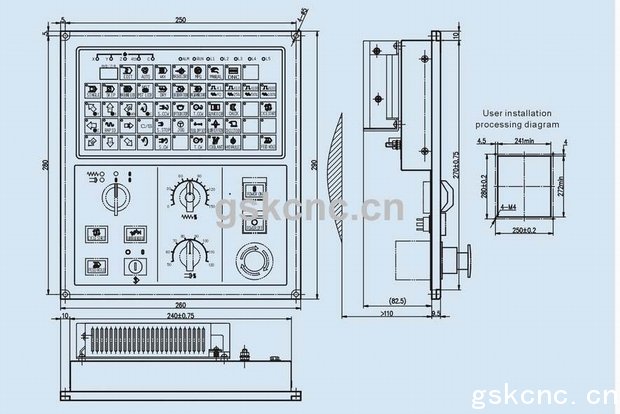

Contour Dimension

GSK988T OVERALL DIMENSION

Operation Panel (A type) Overall Dimension  Operation Panel (B type) Overall Dimension

GSK988T Turning Center CNC controller User Manual download: http://www.gskcnc.cn/uploads/101112/GSK988T_CNC_Turning_Center_Controller_User_Manual.rar |

| Add us to your favorites | Make us your homepage | Language

|